Comparison

with Competing VCR Engine technologies

VCR technologies

have been pursued by almost all industry majors for over a century now (1st attempted by Sir Harry Ricardo, Founder Ricardo UK, 1920). SAAB, Volvo, Nissan, PSA Peugeot-Citroën, Renault, and Global Power train technology leaders like AVL, FEV and MCE-5 of France, Lotus from UK. are invested in VCR methods like Extending Con-Rod/ Crankshaft or entablature Raising/ Tilting Cylinder head/ Bleeding Excessive Compression.

Though test models have empirically proven VCR’s ability to deliver ‘Maximum efficiency’ under all load conditions (today engines perform max efficiency only during highway drive on top gear and not in city drives) along with Multi-fuel flexibility, they remain unviable because of complexities of Slider crank Mechanism.

The approach used by current and past competitors to achieve VCR was with the conventional reciprocating piston crank (slider crank) mechanism that leads to:

-

Incremental addition

in the reciprocating piston crank mechanism requires complicated add-on gadgetries and control systems which makes the entire system extremely cumbersome. This makes it cost intensive to manufacture, assembly and maintain as well as the additional operational and capital costs. Due to the greater number of components the weight and volume of the engine increases.

-

Many VCR engine models

and systems attain only limited VCR range where it can choose between two compression ratios only and hence cannot output analogous variation over a large range.

-

The additional VCR gadgets drain power

provided by the engine for their drive demands. This negates many of the gains in both power and efficiency made by the VCR hence such gadgets are parasitic.

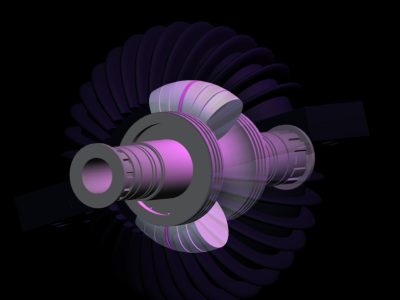

We have developed

a simplified rotary vane kinematic mechanism called “RVCR technology” which combines the performance gains from the rotary mechanism and efficiency gains from VCR, making it the world’s first commercially viable VCR engine.

Combustion system involves extreme complexities. RVCR enables single unified chamber design for all possible differing fuels by its easy external control gear for attaining wide range VCR. CVHE combined by the near spherical combustion chamber and High expansion Rates at slow speeds allows highly efficient Otto-, Duel and Diesel Cycles. This opens the way for 1st feasible and viable method for fuel agnostic capability in one single unified Primemover.

RVCR eliminates the need of dedicated grounded link in mechanism by dynamic reorienting of a part of Rotating links intermittently. This is a new dimension in Machine Methodology.

It further combines efficiency advantages of ‘Positive Displacement Mechanism’; ‘VCR’ with ‘Direct Torque Transfer’, into one.

Contact Us

Phone Number

+91 74030 08844

Email Account

info@gyatk.com

Location

GYATK RVCR Apparatus Pvt Ltd, India,

KGYAT Wind Power Ltd, United Kingdom