Enabling Transformative Kinetics

Explore

RVCR Deep Tech Innovation

KGYAT is the RVCR engineering arm behind a patented energy-conversion and motion-kinematics platform that reimagines how machines move and how energy flows through them.

We develop next-generation engines and green machine technologies based on RVCR, transforming breakthrough concepts into working engines, motors and fluid machines that support the global shift to high-efficiency, low-carbon systems in transport and power.

Why a New Prime-Mover Architecture?

The world faces a climate crisis driven by rising carbon emissions and continued dependence on fossil fuels. Conventional prime movers based on slider–crank mechanisms and turbines are close to their efficiency limits.

While EVs, fuel cells, biofuels and renewables are advancing, most still rely on century-old mechanisms, which means progress is often limited to incremental gains.

RVCR introduces a new prime-mover architecture that can underpin next-generation engines and propulsion systems, enabling step-change improvements in efficiency, emissions and adaptability.

We Are KGYAT

KGYAT is a deep-tech RVCR engineering company at the heart of the RVCR ecosystem. We are the engineering arm that turns the RVCR concept—developed and patented by GYATK—into tangible machines and pilot products.

From design and simulation to prototype realization, we develop RVCR-based prime movers and fluid machines that deliver high efficiency, adaptability and future-ready pathways to zero-carbon operation.

Our Purpose

Our purpose is to move RVCR from concept to reality. We serve as the engineering arm of GYATK within the RVCR deep-tech innovation structure, building green machine technologies that can replace or upgrade legacy systems.

We take RVCR through design, development, prototyping and pilot products, enabling OEMs and partners to integrate RVCR-based machines into their own applications and product lines.

What We Do

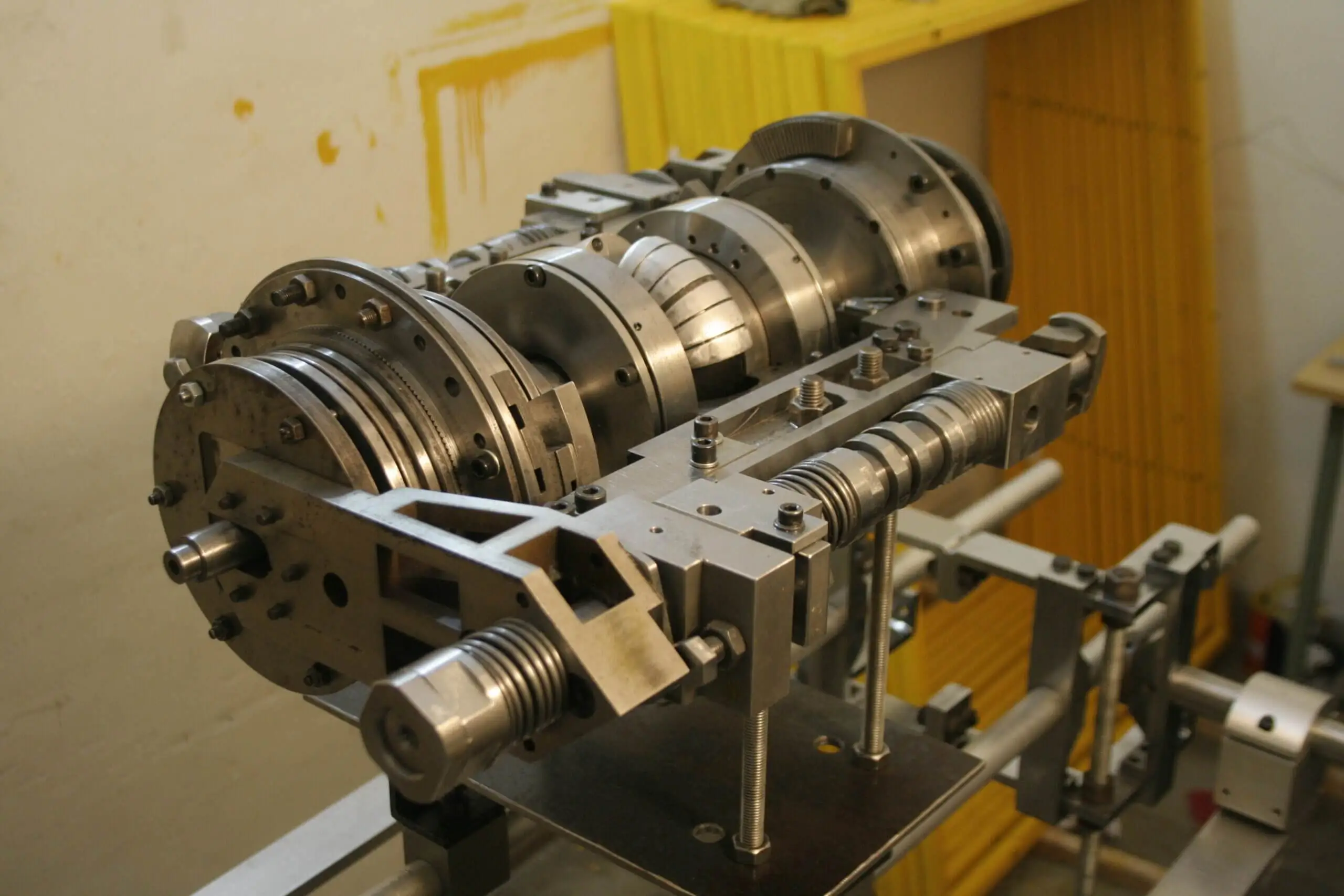

Embedded in the RVCR deep-tech ecosystem, KGYAT pushes RVCR beyond theory and into real machines. We translate novel RVCR kinematics into engineered systems—researching, designing and building working prototypes that move straight into pilot production and commercialization.

From proof of concept to manufacturable next-generation engines and fluid machines, we drive RVCR engineering into action.

RVCR – Kinematics Evolved, Energy Transformed

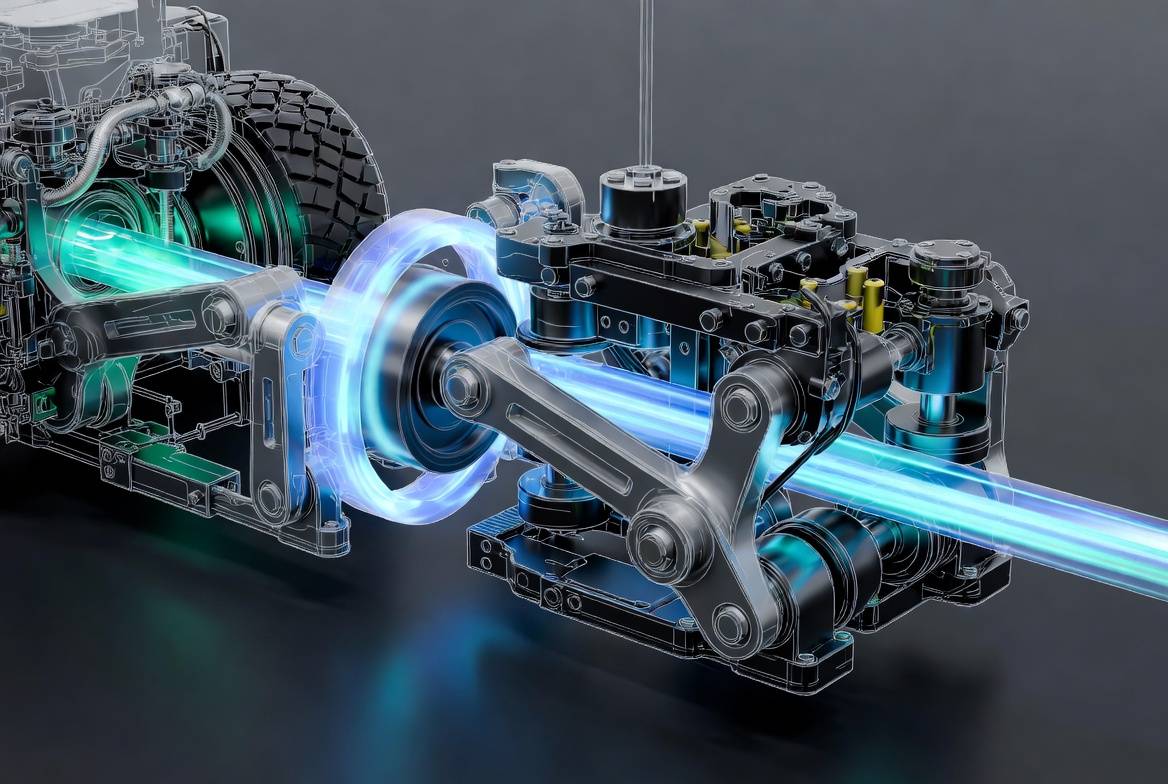

RVCR (Revolute Variable Compression Ratio) is a next-generation energy-conversion methodology. Instead of conventional pistons or rotors, RVCR uses curved “piston-like” elements moving sequentially inside a toroidal chamber to achieve alternating compression and expansion.

This architecture provides a concrete alternative to traditional piston–crank and rotary mechanisms, enabling:

Higher efficiency and performance

Reduced emissions and carbon footprint

Multi-fuel and green-fuel readiness

Compact, modular and adaptable green machine technologie

Our Services

We support partners through every stage of RVCR-based product development, from early technology and business case assessments to prototypes, pilot products and lifecycle support.

Key services:

- Developing RVCR Product Business Case

- Pilot Product Projects & Suiting

- Trials & Validation

- Product Grounding & Life Cycle

Our New Technology Projects

Shaping newer green machine genealogies

We are translating RVCR into a family of new green machine technologies—covering engines, wind motors, hydro kinematic drives, compressors and fluid-handling machines. Each project stream explores how RVCR’s unique kinematics can unlock performance, efficiency and sustainability advantages in real applications.

Our Proposition

Lead the Zero-Carbon Revolution

Establish your leadership in next-generation transport and power systems with RVCR-based machines that go beyond incremental efficiency gains.

Secure Market Exclusivity with RVCR IP

Access segment-specific RVCR IP and technology packages that create a defensible competitive edge.

Build New Markets, Sustainably

Align profitability with environmental and Net-Zero drivers by co-developing RVCR products that are inherently cleaner and more efficient.

Ready to Explore RVCR for Your Applications?

Whether you are an OEM, system integrator or innovation-driven organization, KGYAT can help you evaluate, prototype and develop RVCR-based solutions tailored to your products and markets.